|

|

|

Processing of material in the twin-shaft shredder employs the principle of cutting and scraping material on the edges of discs placed on two working shafts turning against each other. Two sets of tearing discs having the same width with hooks around the perimeter, set on two parallel shafts are the working tools. The processed material takes shape of irregular strips which width is defined by shredding disc width. The processed material falls into the area under the machine on the floor or into a prepared container possibly a conveyor.

The control system prevents the overfilling and overloading of the machine. The control system can even control the drive of the load-up and lift-up conveyors. Moreover, the infeed hopper can be equipped with sensors of minimum and maximum level of material.

The shedder can be equipped by a hydraulic pusher that enables processing of a large volume material (e. g. plastic barrels) by periodical pushing of the material into engagement of shredding discs.

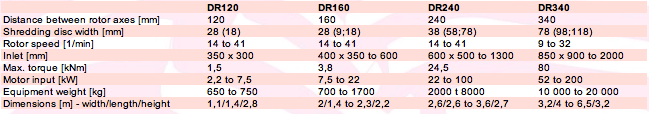

We provide the twin-shaft shredders with wide range of applications in 4 basic variants: mini, light, medium and heavy.

TwinShaft shredders

Partners

Contact us

Eurotools s.r.o. |

tel: 00421 43 413 14 00, 00421 918 924 333 |

|

Legal address, postal address/Store/production: Na Bystričku 14B |

|

|

036 01, Martin ICO: 46 252 401 |

Bank ACC EUR: SK47 1100 0000 0029 2985 8662 SWIFT: TATRSKBX |

|

This website and its content is copyright of Eurotools, Ltd. - © Eurotools, Ltd. 2011. All rights reserved. |